Content

- What are the Advantages of Predetermined Overhead Rate?

- How often should you calculate your predetermined overhead rate?

- How to Calculate a Predetermined Overhead Rate

- When is the predetermined manufacturing overhead rate computed?

- Sales and production decisions based on this rate could be faulty

- Example of Predetermined Overhead Rate

- What are some common methods of factory overhead absorption?

A business needs to estimate its total overheads for a period and estimate its total units or activity basis for the predetermined overhead rates. If these estimates are not accurate, they can end up causing a lot of problems for the business specially if decisions are based on the rates, such as pricing decisions. The common allocation bases are direct labor hours, direct labor cost, machine hours, and direct materials.

- The predetermined overhead rate as calculated above is a plant-wide overhead rate or a single predetermined overhead rate.

- The difference between the actual and predetermined amounts of overhead could be charged to expense in the current period, which may create a material change in the amount of profit and inventory asset reported.

- This means a predetermined overhead rate is a useful formula for planning and making decisions, but it should not be solely relied upon.

- This means that once a business understands the overhead costs per labor hour or product, it can then set accurate pricing that allows it to make a profit.

- If this is consistent for many projects in that department over the past year, then predetermined overhead for that department would be computed by multiplying the estimated cost for direct labor by 150%.

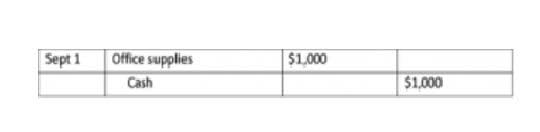

- Remember that product costs consist of direct materials, direct labor, and manufacturing overhead.

A number of possible allocation bases are available for the denominator, such as direct labor hours, direct labor dollars, and machine hours. This means that for every dollar of direct labor costs, the business will incur $0.20 in overhead costs. This means the manufacturing overhead cost would be applied at 220% of the company’s direct labor cost. A predetermined overhead rate is an allocation rate that is used to apply an estimated cost of manufacturing overhead to either products or job orders. Let’s say there is a company, ABC Ltd., which uses Labour Hours as the base for allocating Overheads.

What are the Advantages of Predetermined Overhead Rate?

The best way to predict your overhead costs is to track these costs on a monthly basis. Indirect costs are those that cannot be easily traced back to a specific product or service. For example, the office rent mentioned earlier can’t be directly linked to any one good or service produced by the business. The first step is to identify the total overheads identification for the target period.

- This means that businesses can use the predetermined overhead rate to constantly evaluate its operations without having to wait for actual results to come in.

- The allocation measure is the measurement the cost to make a product or service.

- Predetermined overhead rates are also used in the budgeting process of a business.

- Once the total overheads are estimated, the organization needs to identify the base unit used for allocating overheads.

- This rate is frequently used to assist in closing the books more quickly, since it avoids the compilation of actual manufacturing overhead costs as part of the period-end closing process.

To avoid such fluctuations, actual overhead rates could be computed on an annual or less-frequent basis. However, if the overhead rate is computed annually based on the actual costs and activity for the year, the manufacturing overhead assigned to any particular job would not be known until the end of the year. For example, the cost of Job 2B47 at Yost Precision Machining would not be known until the end of the year, even though the job will be completed and shipped to the customer in March.

How often should you calculate your predetermined overhead rate?

This figure is the sum of costs of the entirety of resources expended during the specific period. This is achieved by dividing the manufacturing overhead cost by the activity base. For example, if a manufacturing business estimates it has $12,000 in overhead costs and a $15,000 activity, the predetermined overhead rate is $0.80. This rate can now be deployed by the business to help them determine the estimated total cost of each job when completed. If an actual rate is computed monthly or quarterly, seasonal factors in overhead costs or in the activity base can produce fluctuations in the overhead rate.

However, the variance between actual overhead and estimated will be reconciled and adjust to the financial statement. A predetermined overhead rate is defined as the ratio of manufacturing overhead costs to the total units of allocation. Finally, as discussed above, some businesses may calculate their predetermined overhead rates based on historical predetermined overhead rate formula information. However, these estimates may produce inaccurate results in volatile businesses where historical information cannot be used as a basis to estimate future data. Businesses need to calculate a predetermined overhead rate to estimate the total manufacturing costs that are borne on the production of a single unit of a product.

How to Calculate a Predetermined Overhead Rate

To calculate the predetermined overhead, the company would determine what the allocation base is. The allocation base could be direct labor costs, direct labor dollars, or the number of machine-hours. The company would then estimate what the predetermined overhead cost would be and divide them to determine what the manufacturing overhead cost would be. Now ABC Co. can compare its estimated results with actual results to evaluate how it has performed. However, whether ABC Co. made a profit or loss on the actual job can only be determined if the price of the job is known.

The period selected tends to be one year, and you can use direct labor costs, hours, machine hours or prime cost as the allocation base. Predetermined overhead rate is an allocation rate that is used in manufacturing, applying an estimated manufacturing overhead to specific periods or jobs. Applying a predetermined overhead rate can be a valuable tool for manufacturers and is commonly used in business. Typically applied at the beginning of a reporting period, the rate can be used to keep track of a number of financial developments and help manufacturing accountants keep a close eye on the books. If the predetermined overhead rate calculated is nowhere close to being accurate, the decisions based on this rate will definitely be inaccurate, too.